Machine vision technology

Machine vision is a field that combines artificial intelligence, computer vision and machine learning to interpret images. Machine vision is used to analyze and understand visual information from images and videos. Computer vision technology is a powerful tool that can be used to detect objects, recognize faces, monitor activities and perform tracking tasks.

Are you looking to integrate machine vision into your production line?

The benefits of machine vision

Integrating machine vision into your manufacturing process brings an even higher level ofautomation and efficiency, enabling you to achieve higher levels of productivity while maintaining consistent quality standards.

Machine vision technology can also be used to control and monitor industrial processes: detecting problems in real time and helping companies to take immediate action to resolve them.

CIM ATLANTIQUE helps you make the most of machine vision in your industrial processes.

Machine vision, a step towards Industry 4.0

Industry 4.0 and machine vision bring a whole new way of thinking about your manufacturing process with industrial robotics and automation! Reduce costs and increase efficiency by integrating robotics and machine vision into your production chain.

Development of industrial mink projects

Our team has been implementing industrial robotics projects for many years, and we’ve seen first-hand how machine vision can help you achieve your goals.

We can advise you on the best way to implement your robotics with machine vision project to get the most out of your investment.

We offer you customized solutions that best suit your needs.

Find out how machine vision can help you achieve your goals.

Examples of machine vision solutions:

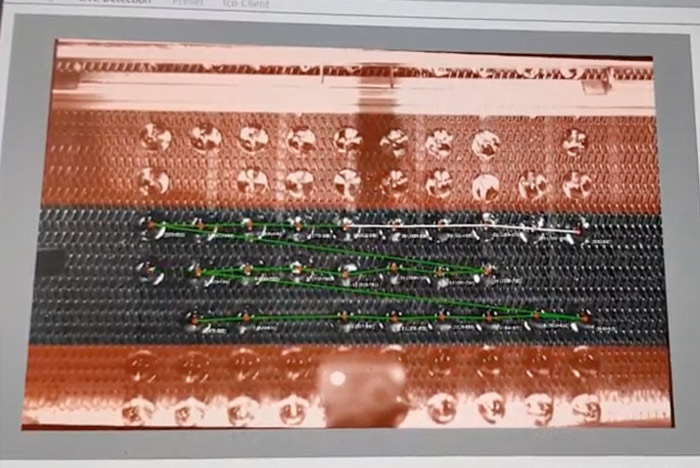

Deep learning machine vision for glass bottles

Our deep learning machine vision software detects the position (X,Y) of glass gobs on a dynamic conveyor.

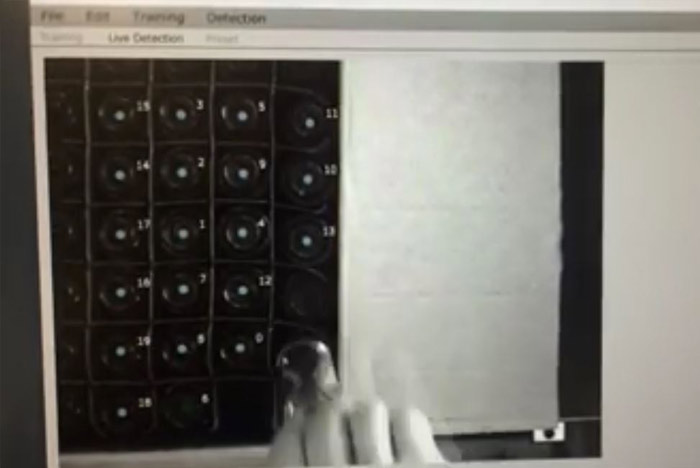

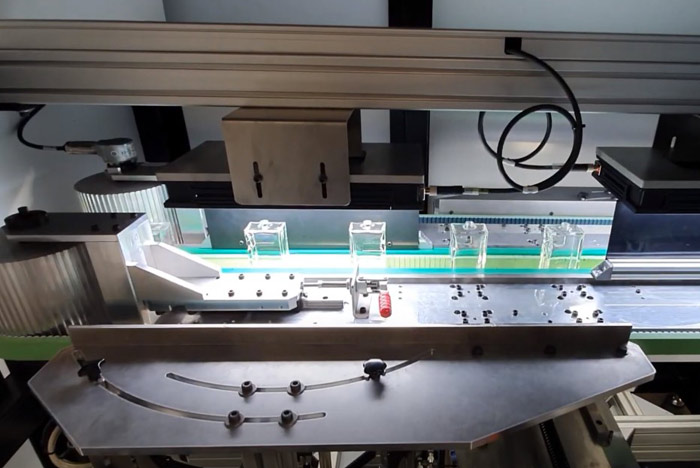

Machine vision for dynamic sensing

Machine vision can be used to detect the position (X,Y,Teta) of vials in different types of container, dynamically on a conveyor.

Industrial vision for the food industry

Identification and detection of several classes of defects in real time at a rate of around 5000 parts/hour.

Industrial vision for joinery

The machine vision system detects and classifies various anomalies (black knots, cracks, missing materials, etc.).

Machine vision for inspecting glass and other packaging

Our industrial vision inspection machine enables the detection and sorting of incised, bouillon and calcination on the bottoms of glass perfume bottles or spirit decanters.

Machine vision components

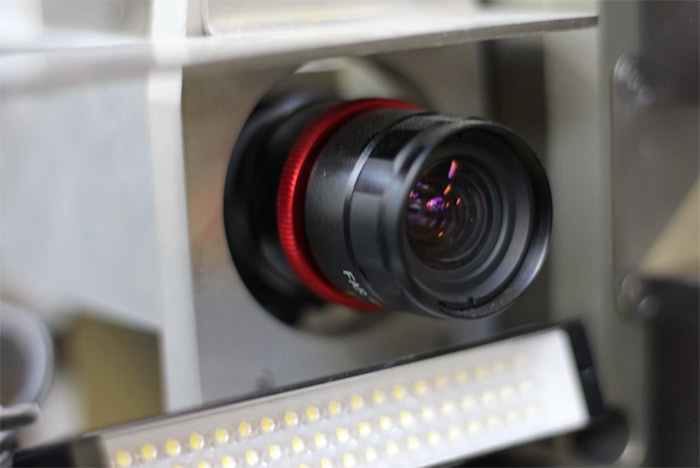

The main components of a machine vision system are lighting, optics and machine vision processing.

- Lighting is one of the keys to achieving satisfactory results in machine vision.

- The optics acquire the image and transmit it to the camera’s image sensor.

- Processing is the process of extracting information from a digital image.

Further information: machine vision

Deep capture, our machine vision software

DEEP CAPTURE, deep learning machine vision software

Deep Capture is a software package developed by CIM Atlantique that uses deep learning to enhance the potential of machine vision applications. Deep learning uses so-called artificial neurons to teach a machine to solve problems automatically, without human intervention.

Deep Capture is the market leader in image analysis in an industrial environment, with unrivalled performance. It enables us to solve complex inspection problems that are usually beyond the reach of conventional machine vision systems.

CIM Atlantique, your machine vision partner

Our machine vision technology enables you to significantly improve productivity. Thanks to our integrated systems, you can monitor the status of your products and processes in real time, enabling you to act quickly to correct anomalies and improve quality and productivity.

Find out more about :