CIM Atlantique has extensive expertise in the design ofrobotized islands at the foot of injection molding machines, and in the development of automated and semi-automated assembly machines for plastic parts.

We understand the different geometric constraints associated with the plastic injection process, and the ergonomic issues at the assembly station. We have expertise in various types of finishing and assembly processes: ultrasonic welding, riveting, press-fitting, tapping, gluing…

The benefits of an injection molding machine

The injection molding machine is used to mass-produce identical parts using plastic injection. It can be useful in many ways. First of all, from an economic point of view, the use of an injection molding machine will greatly reduce costs. Compared with other methods, the production of parts using this machine is quite economical. However, it’s important to note that the benefits will only be effective if you produce a very large quantity of parts (several hundred at least).

Then there’s technical utility. In fact, the injection molding machine will enable you to obtain flawless parts. Surfaces will be perfect without the need for touch-ups. It also ensures a weight/solidity ratio in line with theoretical predictions.

The various components of an injection molding machine

Presses are made up of several parts. The main ones are :

- the nozzle,

- the worm screw,

- evacuation system,

- the feed hopper,

- the closing mechanism.

There’s also the mobile tray, the heating collar and the fixed tray. These different parts can be classified into two main groups: the injection group and the closing group.

How an injection molding machine works

Plastics are supplied by the feed hopper. They are initially in granular form. They are then transferred to the injection unit. The plastic is then melted by the high heat. After melting, it is moved into the injection barrel by means of the auger. The latter is also used to feed liquid plastic into the mold.

This stage is divided into two distinct phases: thedynamic injection stage and the maintenance stage. The material is first moved into the cavities in the mold. It is within the latter that it solidifies following prior cooling. As soon as the temperature is low and the material has solidified (the parts are formed), the ejectors on the injection molding machine take over the task of ejecting it. At the same time, the material has to be moved from the hopper to the auger in preparation for the next injection.

When the parts are removed from the machine, the moving part closes over the fixed part. From this point onwards, the material previously stored in the hopper can in turn follow the transformation cycle.

Prerequisites for using an injection molding machine

The use of an injection molding machine is subject to a prior procedure. This is a two-stage process: a design phase, followed by tool production.

The study phase

It includes an analysis stage, during which the drawings of the parts to be obtained are studied. The study is based on a number of criteria: undercuts, closures, joint planes, etc.

The second stage is the realization phase, during which the design of the tooling needed to achieve the objectives is created. It is based on the defined specifications.

Tooling production phase

During this phase, the mould to be used is made. It can be made of aluminum or even steel. At the same time, various tooling tests are carried out. They give us an idea of the quality of the tools produced, but also enable us to improve them before they are used.

After these various phases, the parts can be produced in industrial quantities on the injection molding machine.

Injection molding machines: our expertise

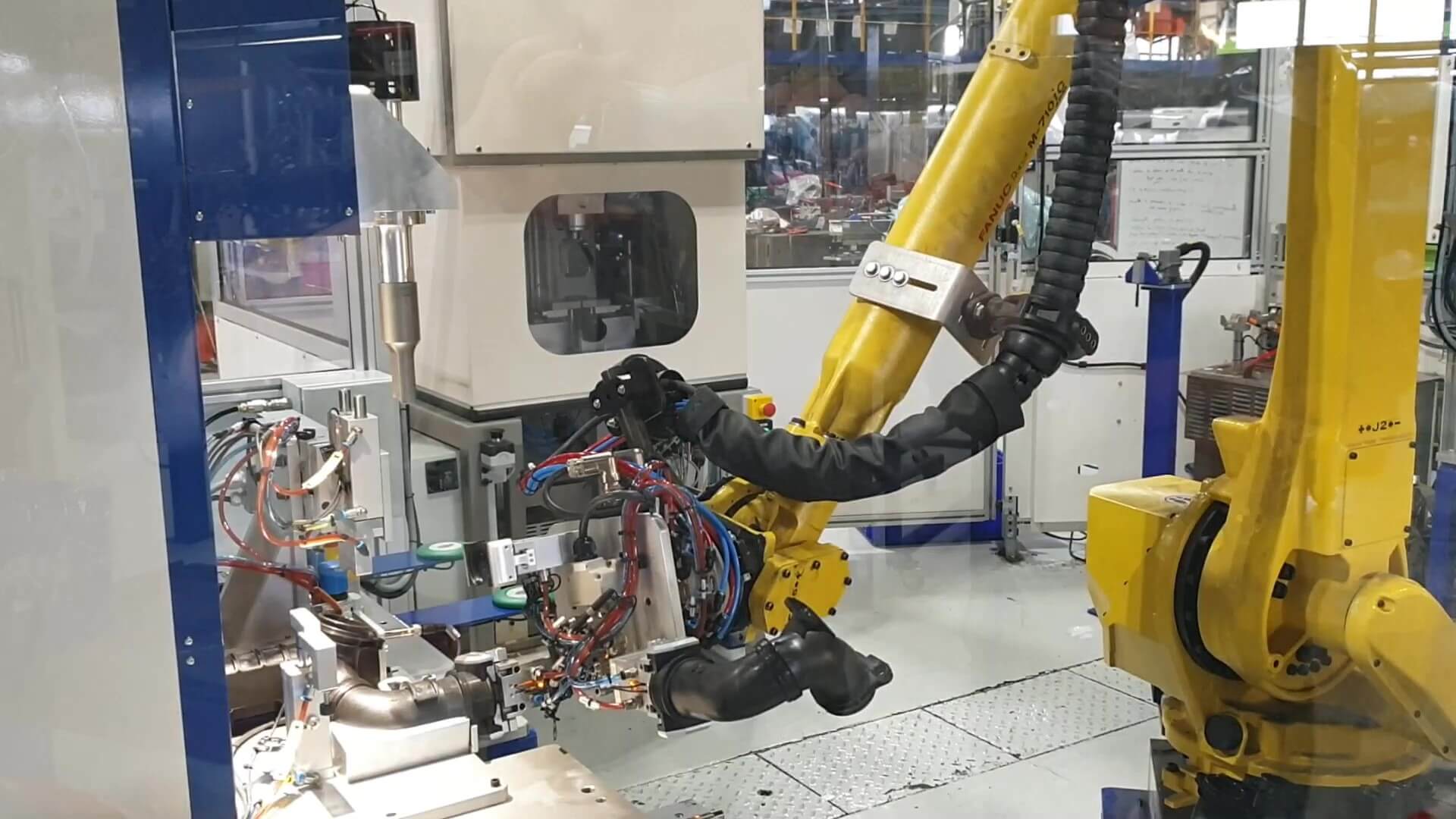

CIM Atlantique integrates 6-axis robots at the exit of the injection molding machine to manage the unloading of injected parts, or the loading of parts to be overmolded. We therefore master the different types of communication and wiring standards (EUROMAP) used by a large number of injection molding machine manufacturers. We are fully aware of the various communication problems associated with this kind of integration.

To optimize on-site set-up times, we usually develop small electrical boxes to validate communication with the press prior to installation of the industrial robot. 6-axis robots offer greater flexibility and versatility than the Cartesian robots usually used in this type of application. It is much easier to add inspection, finishing or assembly operations directly at the press foot. For example, we have developed a robotized island for unloading junction boxes, fitting lids onto the boxes using the robot, and tapping the boxes using a SOMEX head. The cans are then labeled in-line and removed in bulk after shrink-wrapping.

We have also developed a robotized island for transferring and assembling conduits using rotation and US welding.

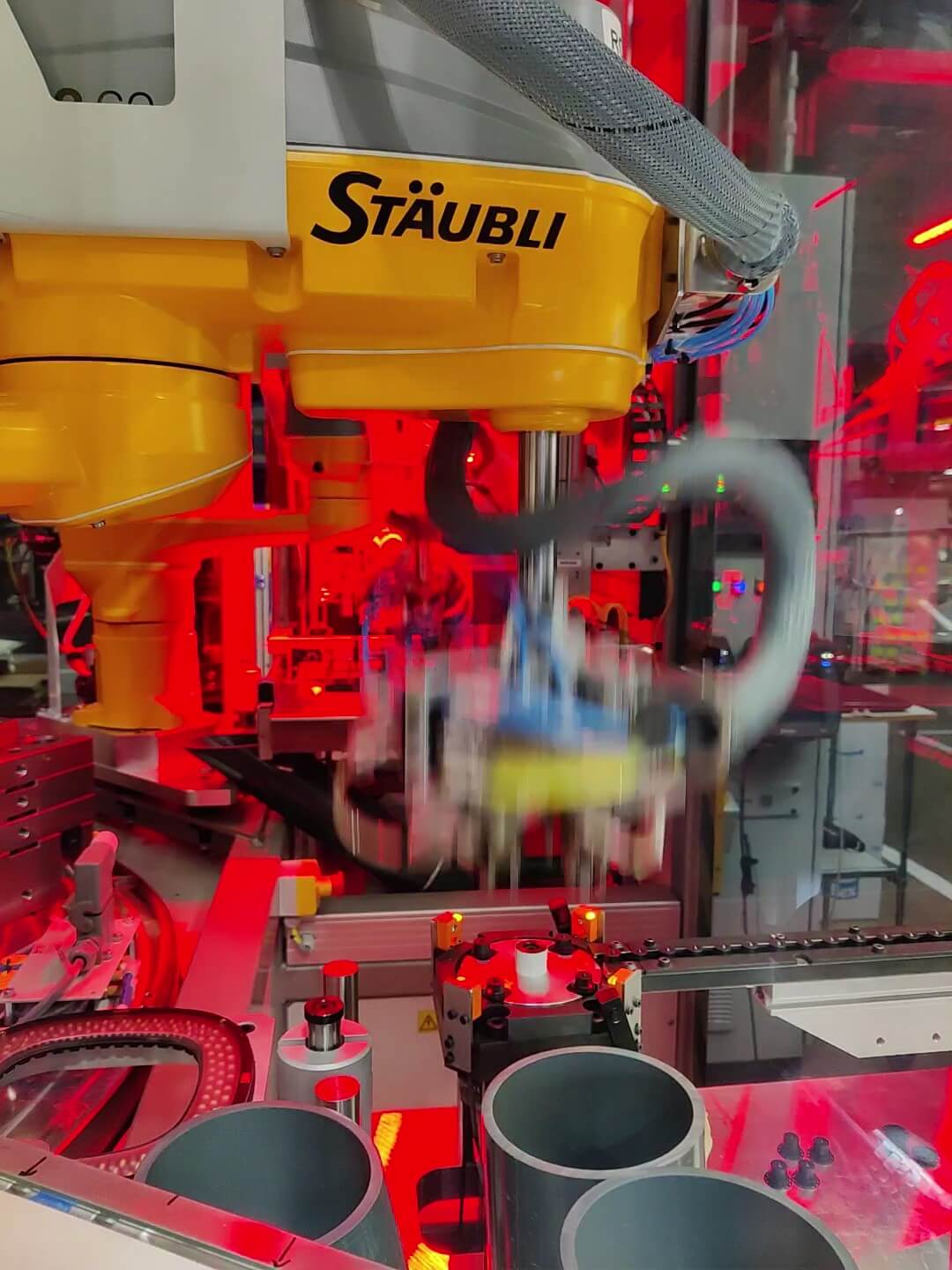

One of CIM ATLANTIQUE’s other areas of expertise is the robotized transfer of parts for overmolding processes. For example, one of our latest projects involved overmolding a plastic hat with a transponder in a plastic shell. We developed a machine with 2 STAUBLI TS260 robots to load hats and transponders into a press with horizontal platen.

What to look for in an injection molding machine

One of the other problems encountered with this type of installation is the diversity of formats to be managed on the same medium. To this end, we develop rapid tool changers, or integrate systems from the market. Tool change can be automatic or manual (dovetail table or ¼-turn changer).

One of the company’s other areas of expertise in this sector is the design of

the design of special automatic

or semi-automatic assembly machines. We regularly develop assembly assistance workstations, and have extensive expertise in press-fitting, leak testing, micro-percussion engraving, etc. We are fully conversant with machine safety rules (operator/actuator distance) and workstation ergonomics. We develop mechanical keying and parameterize poka yoke cycles. In the same way as the robotized islands, our resources can handle different part numbers. To this end, we are developing capacity bases with interchangeable tooling. To ensure rapid cycle changeover, electrical and pneumatic inputs and outputs are wired to harting or Staubli sockets.