Industrial robotics specialist

Over the years, CIM has acquired a wealth of experience in theintegration of industrial robots, which today enables it toautomate robots. Each case is analyzed and then developed to offer robotic solutions tailored to the needs of your industry.

Setting up your industrial robotics project

With its expertise, CIM provides you with solutions for your industrial robotics project. CIM takes care of the programming of your robots, their mechanical design andtheir integration into your company’s environment.

Industrial robotics integration is carried out in strict compliance with safety measures and machine directives (2006/42/CE). ISO 10218-1 and ISO 10218-2 standards are also taken into account during this operation.

And thanks to intensive, ongoing risk analysis, the safety of production personnel is guaranteed.

An industrial robot tailored to your needs

With its team of qualified professionals, CIM begins by dimensioning your industrial robotics project.

The next step will be to determine the loads it will have to bear and its trajectory. The whole process is carried out using CAD software and 3D simulations.

The main types of industrial robots offered by CIM

Most industrial robots are built like human arms. CIM offers you a range of industrial robots to keep your industry running smoothly.

The Cartesian robot

Also known as a linear robot, this industrial robot has three main axes that move in a straight line.

This type of industrial robotics is perfect for anyone who wants a CNC and 3D printing machine. It is also suitable for all metal milling, palletizing and pick-and-place industries …. Once integrated into your company, you can use them 24 hours a day. These industrial robots are renowned for their power and strength.

The SCARA robot

SCARA stands for Selective Compliance Assembly Robot Arm. This machine has two linking arms that enable it to articulate like a human. This industrial robot is faster and easier to use. One of the biggest advantages of this industrial robot is that it doesn ‘t take up too much space, saving you space in your workplace.

This industrial robot is used in the pharmaceutical industry for precise, efficient packaging. These robots are also used in the automotive sector for complex assembly operations.

The polar robot

This type of industrial robot can move and orientate the object it is carrying in any desired direction. It is an industrial robot with 6 axes, three of which are used for movement and the other 3 for orientation.

The polar robot is used for 3D assembly. It is used for welding, and can also be used as a robot manipulator.

In addition to industrial robotics, CIM also offers collaborative robots, uprooting robots, mobile robots and much more. We choose well-known manufacturers such as FANUC, KUKA and OMRON to guarantee our customers quality products and services.

The benefits of robotizing your industry

Integrating industrial robotics into the production chain offers a number of advantages.

Transforming your industry to 4.0

By opting for robotization with CIM, your company benefits from numerous technological advantages, including :

- additional production skills;

- industrial automation of tasks ;

- manage a large number of tasks in a short space of time;

- the consistency and quality of service provided by industrial robotics;

- high production performance;

- maximum precision and reliability.

Added to these are the savings your industry makes by reducing the workforce. This reduction in production costs brings lower-cost products to market.

Optimizing the human-machine interface

Integrating industrial robotics into your production chain also brings many benefits to your company’s staff. The main objective here is to promote harmonious collaboration during service and optimum comfort for the individuals working.

You will benefit from :

- upgrading the skills of your industry’s technicians ;

- a great help with difficult handling tasks;

- fewer sick days;

- securing the production chain.

You also benefit from fast, continuous work. By integrating industrial robotics into your industrial process, you can manage your workforce differently.

So don’t hesitate to contact us with your specific requirements

CIM will come back to you with a plan tailored to your business, using our wide range of industrial robots and managed services to create the optimum solution for your environment.

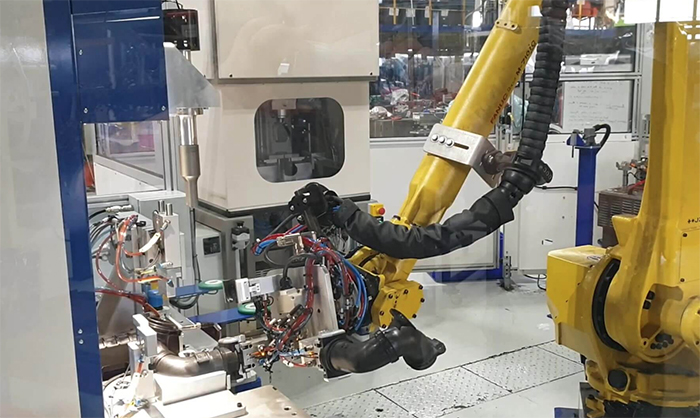

Industrial robotics: Robotic loading and unloading islands

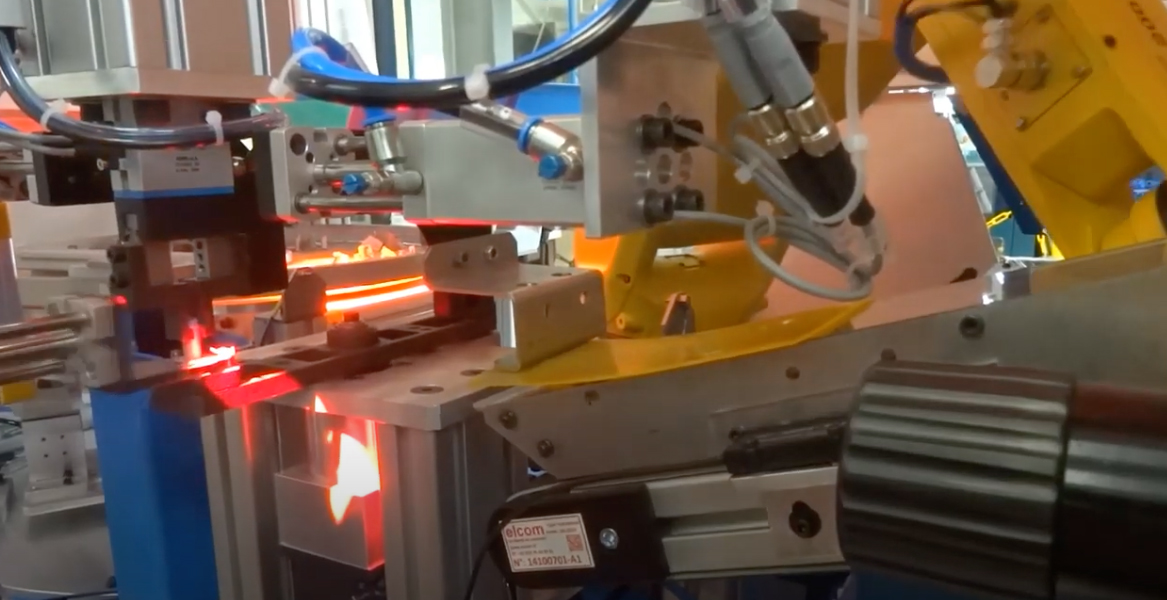

Laser engraving industrial robotics with machine vision control